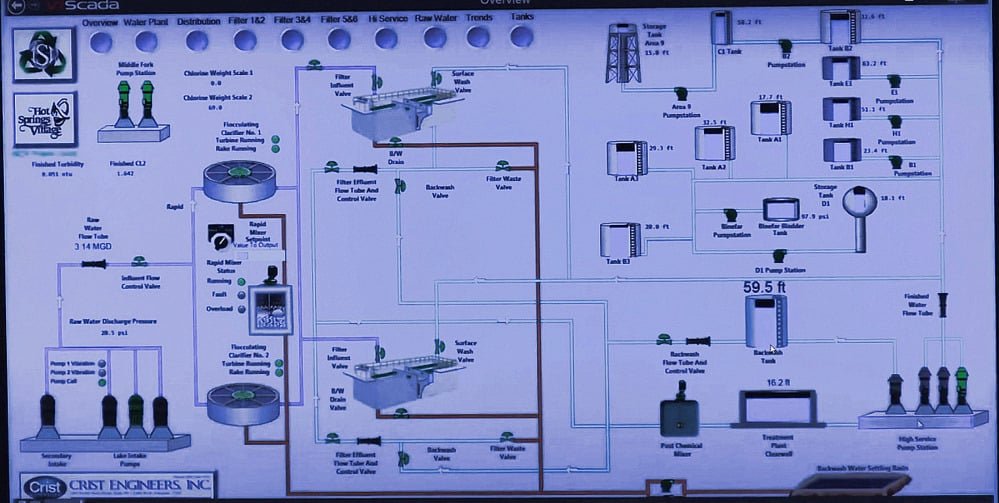

At the February 2, 2022 Board Discussion Session, Public Service Director, Jason Temple, presented a screenshot of the SCADA (Supervisory Control and Data Access) system currently used at the water treatment plant. (See slide below.) SCADA provides computerized systems for both water treatment and wastewater treatment plants in addition to lift stations and other areas when mechanical operations need to be monitored. Temple is asking the Board to purchase the SCADA system for the Cedar Creek Wastewater Treatment Plant. Mr. Temple previously spoke to the Board about this modernization at the Board Discussion Session on January 5, 2022. Click here to read that discussion. This item was listed on the January 26, 2022 Board Meeting Agenda, but the Board did not vote on it.

Temple: “You can see every component, every motor, every facility that has a motor at the water treatment plant on the left side, as well as on the right side you see all of the elevated tanks and pumps that are out in our distribution system…”

Temple: “Some of those tanks have pump stations…In one place, in real time you can see exactly:

- what is on,

- what’s off,

- what’s working,

- what the alarms are,

- if there are any alerts,

- where the tank levels are,

- where your system is working,

- where it is not working,

…in one time and in one spot.”

Temple: Motors can be turned on or off with your computer. You can switch controls. You switch settings if you want that tank to get a little less or more full. This can all be done in one spot.

Temple: We are using SCADA for our water system. We also have this on some of our lift stations, especially the high-priority lift stations, like Cortez. We also have a SCADA system in Woodlands. This was installed to control the HVA Systems. Almost every room has its own HVA system. This gives the ability to turn on the heat and/or air conditioning room-by-room. One room could be using the air conditioning, while at the same time another is using the heat. You can see what the systems are doing and have better control.

Temple: In 2015 our mechanical engineer made a master plan study for our wastewater systems and they recommended that in 2020 that we start beginning to add SCADA systems to our wastewater treatment plants.

Temple: Between 2015 to 2020 we were focused on fixing all the broken motors and equipment. “We were on our last leg on a lot of pieces of equipment at the wastewater treatment plants. We were focused on replacing the infrastructure of the plants to get to a point where we were back in compliance.

Temple: “You might recall, years ago we got in trouble with the Arkansas Department of Environmental Quality over our permit discharges. These permits are regulated by the EPA, which are regulated to the state.” The operators are required to have state licenses to operate the wastewater treatment plants. We are doing that now. Over many years, we have fixed the wastewater treatment plants, both mechanically and operationally. We now meet our permit requirements.

“What is the next step?”

Temple: The next step in the process is to enhance that operation and enhance that control with SCADA.

Highlights of SCADA Memo

Temple: This is a two-part project. Half of it was last year and half is this year.

Temple: “We are asking the Board to authorize the GM to execute a project agreement in the amount of the bid price of $115,826.20 to IDX, Inc., and include any change orders that increase the project price, not to exceed the total project budget of $130,000 for the installation of the complete Phases 1 (which was last year) and Phases 2, this year for the proposed SCADA system at the Cedar Creek Wastewater Treatment Plant.”

Temple: This plant is located behind Lake Balboa on the east side of the Village.

Temple: All of the new development on the east side will be going towards that wastewater treatement plant.

Background

Temple: “This started from our 2015 Masterplan. The plan had this item to be budgeted in 2020. As you recall, we had to wait a couple of years until all reserve funds were paid.”

Temple: “This is the first year that we are financially able to fund a project like this.”

Temple: “Supervisory Control and Data Access [SCADA] provides the following highpoints:

- Better control in operations

- Saves operators time in identifying problems early

- Provides operators more time to focus on needed maintenance

- Lowers the operating expenses by allowing the treatment equipment to increase or decrease our chemical feed systems and power usage based on actual flow rates through the plant (This is flow pacing. You are not operating wide open the whole time. You can ramp down and ramp up based on the flowrate that increases or decreases throughout the day.)

- Better permit compliance which lowers the chance of potential penalties and fines up to $25,000 per day/per violation (There is always this threat. If we have violations, the Arkansas Department of Environmental Quality can always come down on us in that way. And they did a couple of years ago. We had a small fine, but we were already in the process of fixing our plants and they appreciated that and we were a role model in that recovery.) We are close to receiving our regular permit back and be considered ‘normal’ by the Arkansas Department of Environmental Quality. We want to give our staff the tools to ensure that we never fall back into noncompliance.

What is the Return on Investment?

Temple: “This is a lot of money.” Mr. Temple met with GM Hale on Tuesday, February 1, 2022. “I get it. $130,000 you could spend on something like this that benefits the operation plant or we could go put new pumps somewhere else or do something else in our utility structure.”

Temple: “The reason why we’re here today is we did all that in the previous years. We focused on the infrastructure. Now, this is the next phase of operations, moving in from reactive into a proactive mode.”

Where is the Savings?

Temple: There is some operational savings. Temple said he would need to do some more calculations regarding how much electricity, and other operational costs we would save on chemical feed systems.

Temple: “One of the big things this system does is monitor the operation of your wastewater treatment plant 24 hours a day. We man these plants only eight hours a day. Sixteen hours through the evenings and the night, something could fail and we don’t know until the morning when the wastewater treatment plant operator goes to work. It may take some time and by the time the problem is discovered, it may take days to fix an upset wastewater treatment plant or fix the components that are wrong and you run the chance of violating your permit. That doesn’t happen all the time. Sometimes we recover pretty quickly. Sometimes we violate our permit. But that is getting less and less, because our staff are working much better and our equipment is much better today. But, you figure the time it takes for your staff to recover that plant. That is a day or two worth of staff reduction that they could be focused on doing proactive maintenance. It costs about $1,000 a day in labor costs for our staff to get off focus and have to fix something that needs to be repaired.”

Temple: “The other thing is, one example that we know of at the Mill Creek Wastewater Treatment Plant, the one behind Cortez, we did actually add a tiny bit of SCADA system there. One that monitors the flow rate through the plant.” When the operator is at home he is able to access the plant flow rate. He can then come into work, if necessary. We were spending $10,000 in overtime for those operators to come in and babysit the wastewater treatment plants when we were having high flow or when they didn’t know what was going on because they didn’t have SCADA and it was necessary to come into the plant to see. There is a savings there.”

Temple: “If you figure $10,000 a year or more in savings, your ROI [Return on Investment] is somewhere around five to ten years for the savings to pay for the investment. But if we ever get in trouble, it [pays for itself] a whole lot quicker. There it is. That is kind of the big picture of why we are doing this, how we got to this day. Half of it was budgeted last year. Half of it was budgeted for this year. What you are doing is, you are investing in your infrastructure, in the operation of your infrastructure and the future operation of your infrastructure.”

Temple: “Right now we have exceptional operators out there. Charles Hicks is a 45-year employee of the Village.” He has been involved in wastewater treatment plant operations the entire time. Someday he won’t be here. The future staff may not have that wise person here and they need all the help they can get to manage a wastewater treatment system. Wastewater is a living organism. You have to keep it alive in order for it to work right. You need to know what is going on in your system to anticipate and avoid problems quickly, versus having to recover over a period of time. That is it in a nutshell.”

Temple: The prices are listed on the document. We requested bids from three different vendors:

- Instrument Supply,

- Jack Tyler,

- IDX, and

- Brown Engineers.

Temple: And we didn’t get a bid from ISI. We got a bid from Jack Tyler and IDX. IDX also gave us a Phase 2 bid. Brown Engineers didn’t. The IDX system we are proposing for the wastewater treatment plant is the exact SCADA system we have been using for eight years and it has operated perfectly. “Our staff are very comfortable with it.”

Temple: “If we are going to go forward with SCADA, it just makes sense going forward with something that we’ve already been using and has worked well for the Village.”

Temple: “The price there is $115,000 and we have $130,000 budgeted, just in case there are price increases…”

GM and Board Comments/Questions

General Manager, Kelly Hale: “Anything like this I see shiny objects, bells, toys to play with. I was pushed back on those a little bit. I have used similar systems like this in my past career with automated facilitites….I support putting this in and from this positon.”

Hale: “I asked Jason to move it forward with anything he has, be able to show the ROI, because you are talking about electricity. We’re band-aiding these sewer and water treatment plants together. Chris you and your team are excellent. Very skilled at what you do. They are making filet mignon out of hamburger. We don’t even see it behind the scenes – there is a lot more. When I sit and tell you, just in a snapshot of spending time, we’ve got a $3 to $5 million liability in our sewer and water treatment, eventually. Not right this moment. But to start replacing all the parts – we have some parts that are $600,000. And it is simple for people to understand. You turn on the faucet and clear, clean water comes out. You flush the toilet, it goes away. That’s what our customers expect from us.”

Hale: “With that being said, this here is kind of the building block for the future purchases we are going to have to end up making investments in down the road. What this will do, I believe is be able to help us monitor and stay ahead of some of these parts, these motors, and clarification systems that we have and babysit them a little bit better so we don’t put any excess strain on them to get a better life cycle out of them. A lot of these are past their life cycle – three, five, even ten years in some cases.”

Hale: “When I say, ‘band-aiding together,’ this unit will enhance us getting longer to be able to save up more money and do the things and be a little bit more proactive that we’re not having to make a decision at the 11th hour to write a check for half a million dollars for a part that we have got to have. We’ve got four, five, six of those that cost $500,000/$600,000 for one unit. They are big-ticket items.”

Hale: “I think this here will help manage through that process. But I also think there is a savings and Jason, I ask you and Chris to do the leg work on the electricity use savings, the water excess cost on that. Troubleshoot this with the labor costs on overtime rates and get a true ROI to pay for this thing. But I think being able to babysit the stuff we do have, for lack of a better word, is worth the money at this point in time. Fair enough?”

Director Bob McLeod: “Jack Tyler was half the price of IDX. What’s the reason for that?”

Temple: “Look at it from the point of a Phase 1. We had a Phase 1 bid for last year’s cost and so Jack Tyler was $55,000. IDX was $49,000. Those two are apples to apples.”

Temple: “We did go see Jack Tyler’s system over at the City of Hot Springs and it’s good. Both were viable. We just have more experience with this one and it was a little bit cheaper.”

Temple: “IDX just happened to give us the next phase of pricing and this is for informational purposes for the Phase 2 part of it. Here is the thing. If we awarded the project last year to IDX based on their $49,000, from here on we would not go out for bids. We would simply add on to that system. That is what that second price from IDX is for.”

McLeod: “IDX is two phases and Jack Tyler is only one phase.”

Temple: “That is correct.”

As this was a Discussion Session, no votes were taken.

By Cheryl Dowden, February 6, 2022

✼✼✼✼✼✼✼

Thank you for visiting Hot Springs Village People. If you like, please comment below; we love to hear your opinion. Thank you for keeping the comments polite and on top

ic. Please use your real name. If you are an HSV Property Owner, please join us in our private Facebook Group. Click here to join the group. If you would like to submit an article for publication, please contact us through this website. Be sure to bookmark this website.